With the use of selected fillers, the properties of the polymers are adapted so that they can be reliably detected by X-ray and metal detectors. The production of the compounds by compression molding allows a high filler content while maintaining good mechanical properties.

The individual adaptation of the recipes enables material properties that are perfectly matched to your process.

With the aid of high-density mineral fillers, the overall density of the compound can be specifically adjusted. In this way, sufficiently high-density differences to the surrounding food or cosmetic product can be achieved, which enables reliable X-ray detection of the compounds – X-Ray Detectable.

To be able to detect a polymer with the aid of a metal detector, it is necessary to give it properties which influence the electromagnetic field of the detector. This can be achieved by using magnetic fillers. The resulting increased density of the compound simultaneously enables X-ray detection – Dual Detectable.

High strength at low density - just one reason why high-performance polymers are often used as metal substitutes.

Whether hot or cold - high-performance polymers cover a wide temperature application range while maintaining good mechanical properties.

Hygiene is of great importance in the food and cosmetics industries - regular cleaning and sterilization of polymer surfaces is no problem.

Thanks to the chemically stable structure, product adhesion to the polymer surfaces is greatly reduced.

Our solutions consider the requirements of FDA and EU regulations

The high-performance polymers used at STASSKOL (e.g. PTFE and PEEK) have no significant water absorption and are 100% resistant to hydrolysis, even in superheated steam applications.

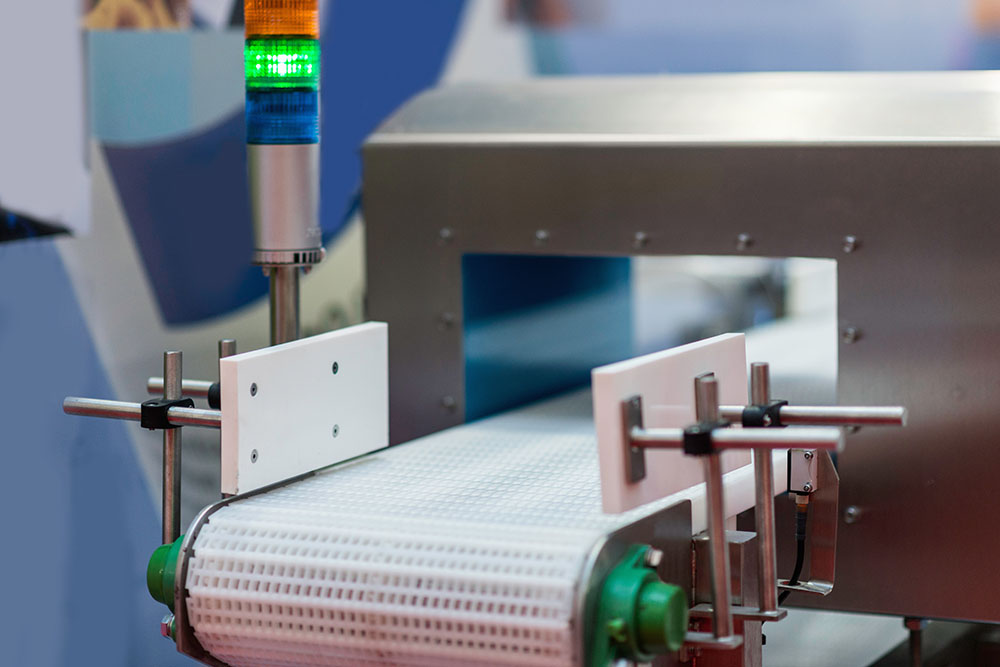

Every material development goes hand in hand with the characterization of material properties. With the support of our partner METTLER TOLEDO, a leading manufacturer of product inspection systems worldwide, detectability tests can be performed under conditions as close to reality as possible. In doing so, the test is not only performed in air, but inside a food product with a representative density.

Learn more about the test procedure here.

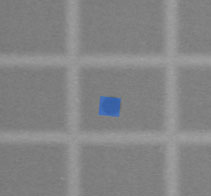

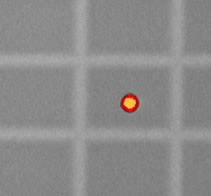

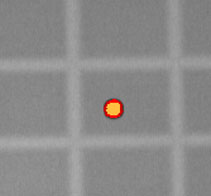

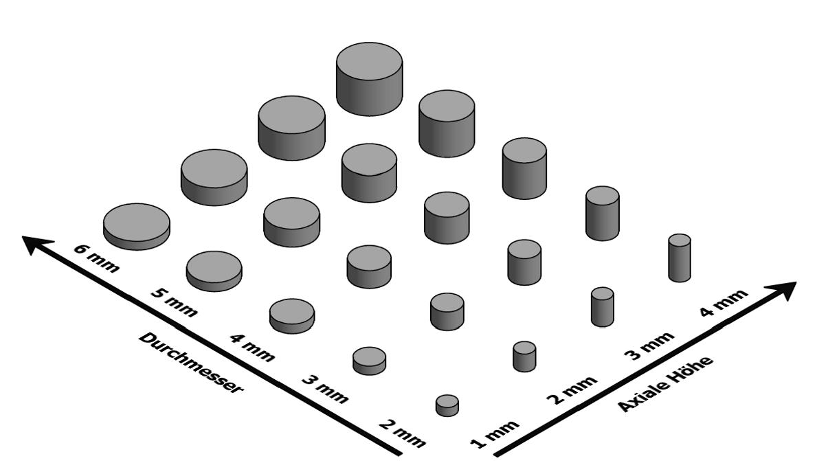

The results obtained demonstrate the reliable detectability of both solution strategies. The high filler content of the compounds enables the unambiguous detection of foreign bodies from a size of 2 mm (see picture) in the X-ray and metal detector. Depending on the surrounding product and acting product effects, the detection of even smaller foreign bodies is also possible.

Request free test sample cards here to be able to test our materials under your production conditions.

Especially in X-ray detection, the product surrounding the foreign body is of high importance, as it significantly influences the results. X-ray detectors detect contamination based on density differences. Ionizing radiation is attenuated more by a high-density material than by low density materials. This is also true for the wall thickness of the material through which the X-rays pass. A high wall thickness causes increased attenuation. Different degrees of weakening effects show up in the form of contrast differences on the grayscale images of the X-ray detector. These are analyzed and contaminated products are rejected.

To be able to look at all these influences in more detail, the following experimental setup is available:

To test our material developments under the most realistic conditions possible, the detection tests are not carried out in air (density ~ 0.001 g/cm3), but within a food product. Since most foods are water-based, a density of 1 g/cm³ is usually assumed. Deeper analysis shows that the density of food can be higher, which in turn complicates X-ray detection. For example, chocolate in our test has a density of 1.2 g/cm³.

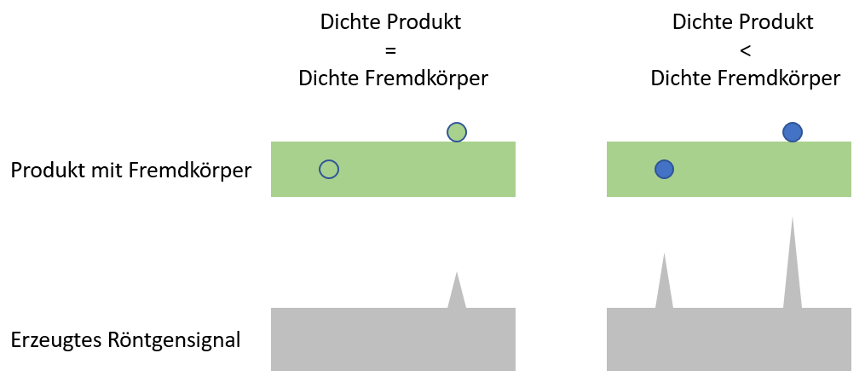

The influence of the increased wall thickness due to external placement of the foreign body can falsify the measurement results. This can be particularly illustrated if the foreign body has the same density as the surrounding product. The figure illustrates the effect. A foreign body that has no density difference to the surrounding product is invisible to the X-ray detector if it is inside the product. If the foreign body is outside the product, the total wall thickness increases and the X-ray detector perceives a signal, although the plastic has no detectable properties. Now, if the polymer is an optimized material with a higher density, the foreign body will produce an increased signal when it is outside the product. However, this result has been distorted by the wall thickness influence. The true signal produced by the detectable polymer is lower.

Therefore, in the tests carried out by STASSKOL and METTLER-TOLEDO, the foreign bodies were embedded in the chocolate in such a way that the sample thickness could be kept constant.

This made it possible to identify the true signal of the impurity.

The influence of the increased wall thickness due to external placement of the foreign body can falsify the measurement results. This can be particularly illustrated if the foreign body has the same density as the surrounding product. The figure illustrates the effect. A foreign body that has no density difference to the surrounding product is invisible to the X-ray detector if it is inside the product. If the foreign body is outside the product, the total wall thickness increases and the X-ray detector perceives a signal, although the plastic has no detectable properties. Now, if the polymer is an optimized material with a higher density, the foreign body will produce an increased signal when it is outside the product. However, this result has been distorted by the wall thickness influence. The true signal produced by the detectable polymer is lower.

Therefore, in the tests carried out by STASSKOL and METTLER-TOLEDO, the foreign bodies were embedded in the chocolate in such a way that the sample thickness could be kept constant.

This made it possible to identify the true signal of the impurity.

With an increased wall thickness, the probability of an X-ray particle colliding with the electron of the matter increases. The beams are weakened more strongly. To be able to analyze this influence more closely as well, cylindrical test specimens of defined sizes are made from the compounds.

In this way, it is possible to give an assessment of the detectability of particles and foreign bodies which do not have a clearly defined shape. In the tests carried out, even the thinnest sample shapes could be reliably detected. These results speak for themselves.