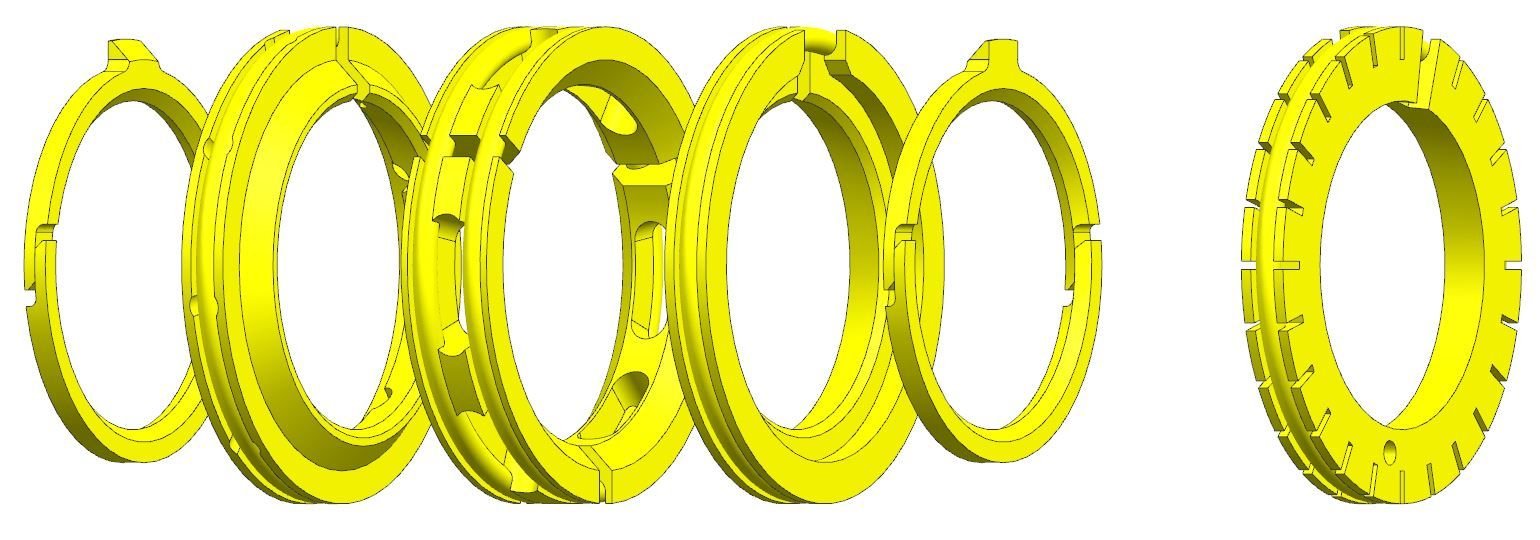

The non-metallic oil wiper packing combines two 3-piece main scrapers, a tension ring and a pre-scraper. The scrapers are made of PTFE an PEEK materials produced in-house. Due to the materials the piston rod is preserved.

The BOSS was already registered for a patent.

Oil wiper packing prevents that the transfer of the lubrication oil from the crankcase via the piston rod to the distance piece. In order to do this, a very accurate manufacturing of the wiper edges is required.

STASSKOL oil wiper packing achieves nearly 100% oil wiping. Thereby the cost saving by reducing the oil consumption.

Efficient oil removal is guaranteed by generously dimensioned return grooves. Always use appropriate return grooves in both, packing and corresponding crankcase.

While mounting the oil wiper packing, recommended clearances must strictly be observed.

Because of the split design it is possible to carry out a change of sealing rings and oil wiper rings without disconnecting the piston rod from the cross head and piston. A change of the complete oil wiper packing is only possible by disconnecting the cross head and piston rod.

The use of a mounting sleeve or a mounting cone is required when installing new sealing rings and oil wiper elements. Make sure the sealing and wiper surfaces are undamaged and jamming of segments is prevented, the sealing components must be mounted in the appropriate order and direction also