Special applications require special recipes which repeatedly push the limits of what is feasible.

Use our competence in polymer processing to obtain the ideal material for your application in customised dimensions and thus to optimise the cost/benefit ratio. We continuously develop our processing methods in accordance with our customers’ needs.

STASSKOL is your polymer specialist, starting with the development of high-performance polymers, via processing, up to the complete final product.

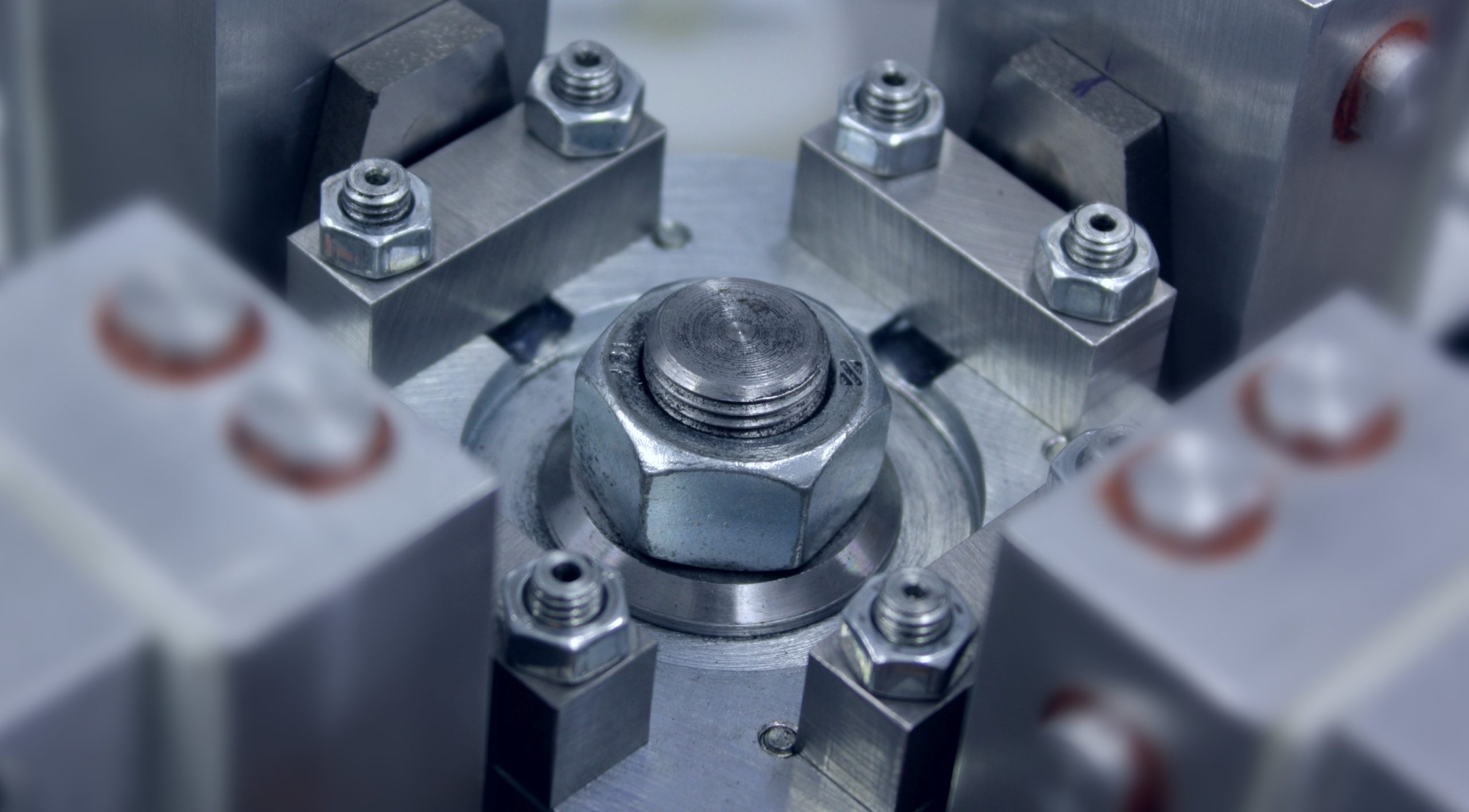

For cost reasons, not all components and polymeric materials can be manufactured using the die injection-moulding process. We are specialist in the mechanical processing of high performance compounds on CNC-controlled lathing and milling machines. We can offer sketches and samples of and manufacture the construction parts in accordance with your individual CAD drawing specifications. Our state-of-the-art and flexible plant enables precise processing of a very wide range of construction parts. Several years’ experience and constant further development of staff and manufacturing technology enable us to realise demanding construction tasks according to individual customer drawings.

Your construction components are CNC polymer processed using a wide range of conventional and CNC-controlled lathing and milling machines.

Due to the considerable manufacturing depth, it is also possible to process large dimensions and diameters.