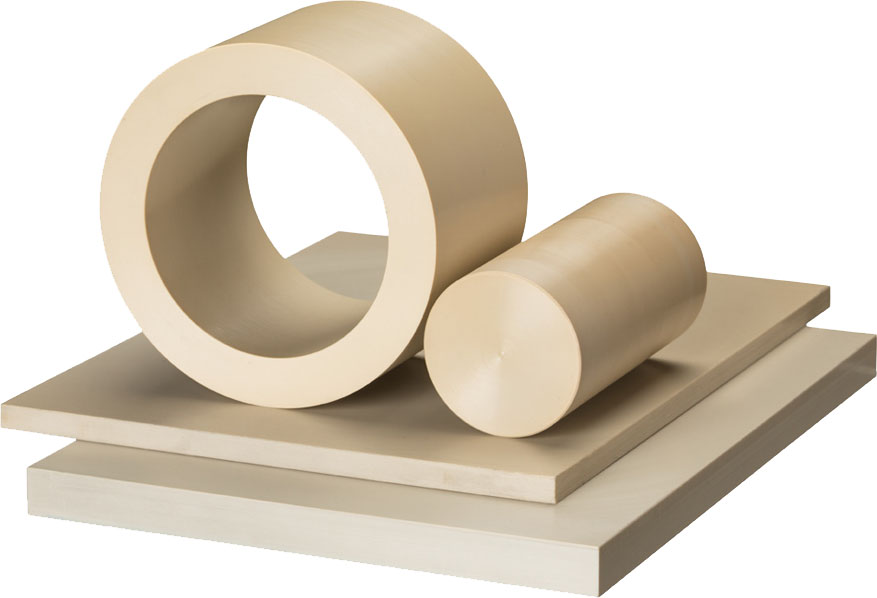

Thanks to the addition of selected fillers and production using the hot or cold pressing process, STASSKOL’s high-performance plastics have outstanding properties such as permanent temperature resistance up to 300°C, wear resistance in high-pressure processes up to 1,000 bar and resistance to acids, greases and solvents. STASSKOL is also able to produce materials up to a diameter of 1,400 mm. STASSKOL materials are available under the names ESKAPEEK (PEEK), ESKAFLON (PTFE), ESKASINT (PI), ESKATRON (PPS), ESKABASE (polyethylene) and ESKATECH (polyamide). You can choose from a wide range of material compositions. We will be happy to assist you in selecting the optimum plastic for your application.

A large number of tools are available for manufacturing the bushings. On the one hand, this enables countless combinations of inner and outer diameters in small size increments. On the other hand, bushings can be produced with dimensions that optimally approximate the customer’s finished product. In this way, material losses and production times during further processing are reduced to a minimum.

In addition, the materials can be given an individual color, which means that the finished parts can be easily assigned to the manufacturer when installed.

Another special feature is the production of bushes with an external diameter of up to 1,400 mm. As there is a large selection of large-dimensioned tools available, STASSKOL also manufactures these unusual diameters at fair prices.

Please send us your inquiry.

Solid rods are available in various diameters and heights and in a wide range of material compositions. Even small quantities are available at low cost. As STASSKOL already produces the solid rods in the dimensions that come closest to your finished part, there is no need to cut them to size and there are no unusable offcuts.

We will be happy to advise you on the selection of the optimum high-performance plastic for your specific application.

Cuttings made of PTFE, PEEK, PI, PPS, PA and PE are available in a wide range of thicknesses and colors. Even unusual shapes can be produced according to your specifications. The blanks are also produced using a hot or cold pressing process, resulting in exceptionally resilient materials.

We will be happy to advise you on the selection of the optimum plastic for the intended application.

However, the company not only offers semi-finished products, but also professional processing into finished components. These components can be sealing rings, bearing bushes and much more. They are manufactured according to customer drawings. For this purpose, the company has state-of-the-art machinery with special turning and milling machines that can process not only plastic but also metal. This makes it possible to manufacture plastic-metal parts, which can also be supplied fully assembled on request. It is also possible to provide the components with an individual laser engraving of the logo or an article number. Of course, STASSKOL also offers the complete package, in which the component is designed and manufactured based on the installation space. Here, too, the selection of the optimum material for the respective application or requirement comes first.

We will be happy to provide you with an appropriate quotation.