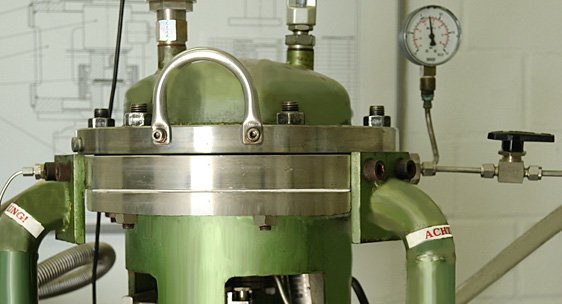

The reciprocating test bed is a compressorwhere we can test materials under operational conditions. In this special testing machine the pressures and temperatures can be entered electronically in each of the 6 chambers of a piston rod packing. Through the combination of digitally entered temperature, pressure and leackage data the element’s performance can be examin. For this reason, STASSKOL is able to develop the optimal combination of material and sealing ring design for customized applications. Performance Characteristics: – simultaneous test of 4 piston rod packings – piston rod packings in vertical and horizontal arrangement – different process gases (H2, N2, Natural Gas, CH4 etc.) – final pressure up to130bar – variable dew point up to -90°C – cooled and non-cooled piston rod packings – digital measurement of leakage of the piston rod packing.

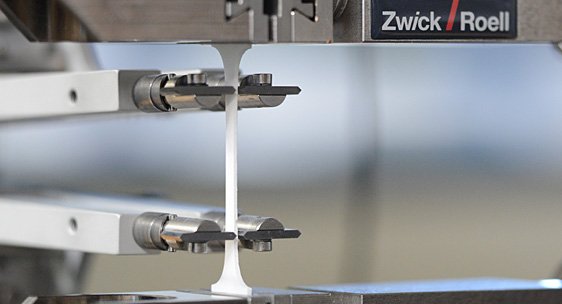

STASSKOL uses the rotating tribometer to simulate applications with uniform movement stress. The recorded data can be used to characterise the materials tribologically. Performance data: – Continuous measurement of the wear path, the coefficient of friction and the temperature – Sliding speeds up to 6 m/sec – Variable contact pressures – Interchangeable mating surfaces (cast iron, steel, etc.) – Mating surfaces can be temperature-controlled from 40 °C to 150 °C – Various gaseous media (H2, N2, CH4, etc.)

Translated with www.DeepL.com/Translator (free version)